The gluten-free market is experiencing rapid growth driven by increased awareness of coeliac disease, gluten sensitivity and growing consumer demand for healthier dietary options. Replicating the texture of traditional baked goods, without gluten can be a significant challenge.

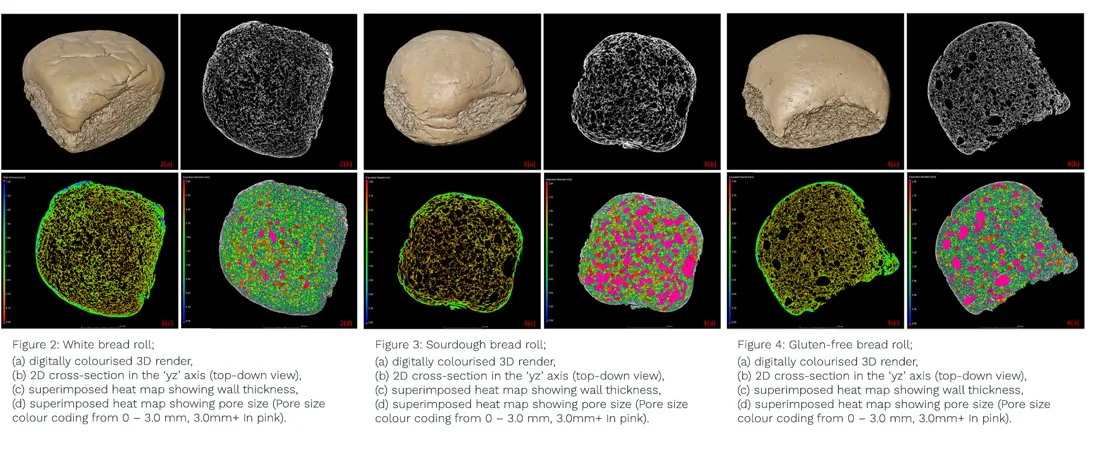

This case study showcases how RSSL partnered with a leading UK Bakery to solve these challenges. By leveraging the power of microstructural analysis using 3D Imaging and Micro-CT, our detailed analytical insights helped our client improve overall performance of their gluten-free bread rolls and ensure maximum consumer satisfaction.

The challenge

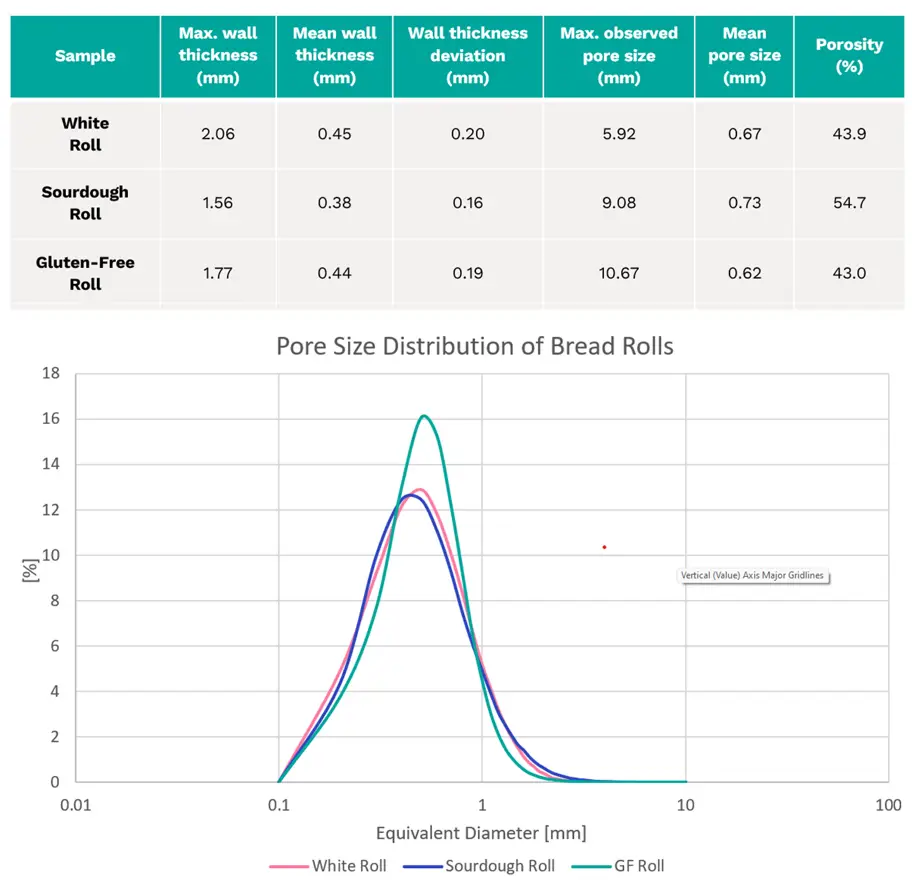

After expanding its bakery line with a gluten-free bread roll, our client needed to understand why it had a disappointing, crumbly, gummy texture compared to a standard white alternative. We were tasked with providing relevant analytical data to explain how removing gluten had affected the physical properties of the bread and what changes needed to be made to improve the recipe.