Starch retrogradation is one of the main reasons bread goes stale. Freshly baked bread has a soft, moist and elastic crumb due to the gelatinisation of starch and presence of water. However, as the bread cools, starch polysaccharides (mainly amylose and amylopectin) start to reorganise themselves into a more crystalline structure. Over time, this makes the crumb firmer and causes the pore structure to shrink or collapse, leading to a drier, denser, less elastic texture. A moisture gradient is also formed during cooling. Differences in vapour pressure cause the migration of moisture from the crumb into the crust, resulting in lower crumb moisture and higher crust moisture1.

RSSL was asked to evaluate the extent of these changes in a white baguette, so our client could make the right formulation adjustments to maintain its freshly baked, light and airy texture for longer.

X-ray micro-CT (computed tomography) uses non-destructive X-rays to capture cross-sections of an object at different angles through 360° for later virtual reconstruction.

Visualisation of materials is based on their relative densities, with density of the material being inversely proportional to the measured intensity of X-ray photons. Scans were taken using Werth Metrology’s Tomoscope XS Plus. Once acquired, the datasets were processed in Avizo 2023 (3D image analysis software) before being exported to VGstudio Max for structural thickness and porosity analysis.

A white bread baguette was analysed at day 1 (T=0, fresh). To accelerate starch retrogradation, the baguette was then placed in a fridge before analysis on day 7 (T=1, stale). The structural thickness and pore size were calculated, as well as % porosity by total volume.

Based on inferred literature values, significant changes in moisture content and crystallinity would be observed in bread stored at 4°C2:

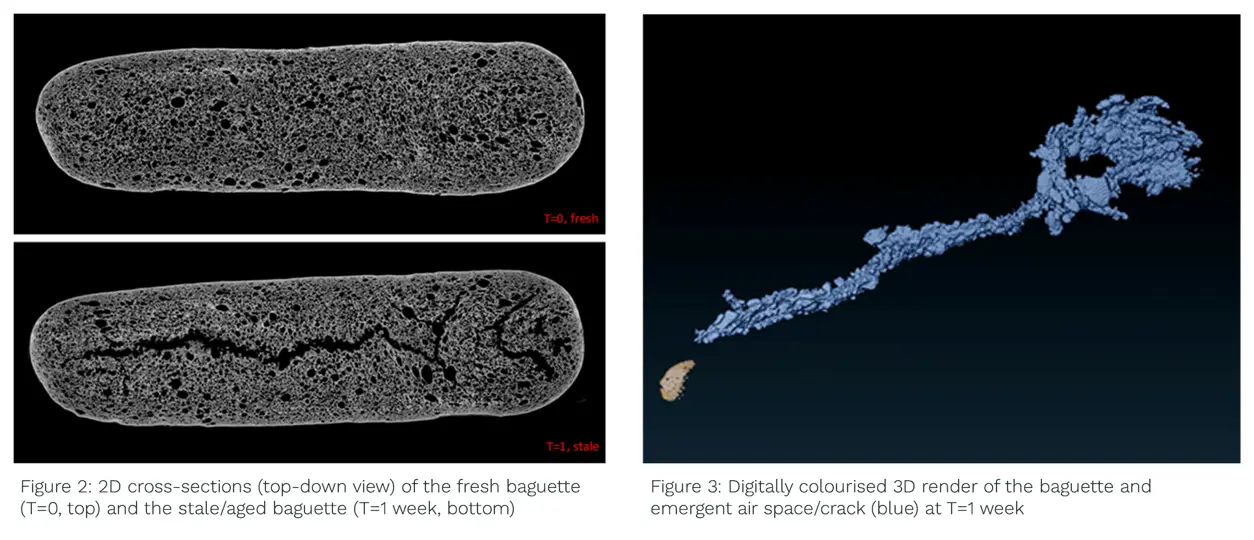

Micro-CT allowed visualisation of 2D cross-sections within the baguette, as well as the creation of a 3D render.

When the baguette is fresh, the crumb is soft, moist, and elastic due to the gelatinization of starch and the presence of water distributed throughout the crumb structure. The internal structure is characterized by a light, open, and airy network, with starch and gluten contributing to its softness and flexibility.

As the bread ages and retrogradation occurs, the internal structure becomes firmer and more rigid. Amylose retrogrades faster than amylopectin, forming crystalline regions that lead to a tougher, denser crumb. The internal structure loses its elasticity, and the crumb becomes more brittle. This results in a reduction in the flexibility of the starch-gluten network.

Figure 1: Digitally colourised 3D render of the baguette

Visually, the micro-CT imaging showed a clear difference between the two time points, with some pores of the stale baguette appearing to have collapsed. Large cracks can also be seen throughout the bread as it ages. 3D visualisation of this emergent crack showed a large, interconnected network throughout the baguette.

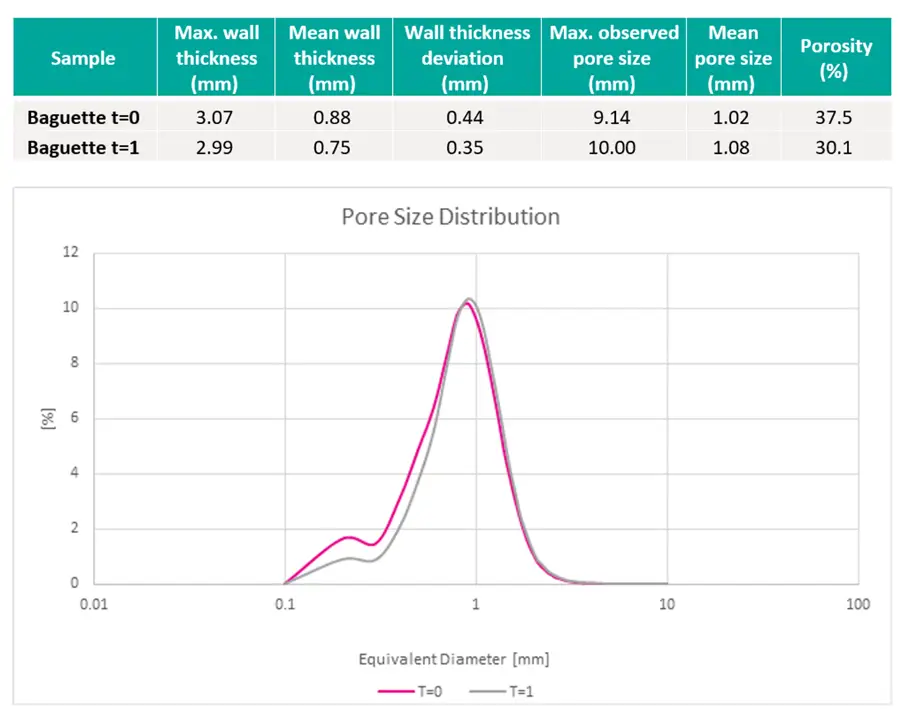

Figure 4: Distribution of pore sizes within the baguettes at T=0, fresh and T=1 week, stale.

Microstructural analysis determined that the mean wall thickness decreased with aging. This may be due to the expulsion of water (syneresis) from the starch polymer network, causing shrinkage. An overall decrease in the baguette volume was also observed, consistent with this observation. Volume decreased from approximately 750 cm3 to 670 cm3.

Pore size distribution was comparable between the two time points; however, the aged baguette had a slightly larger maximum pore size (due to the collapse of bubbles and large internal crack propagation).

Porosity % was corrected to remove the large air space/crack which had appeared – a decrease in this value is likely related to the decreased overall volume and the appearance of the crack which had connected several pores together.

RSSL’s micro-CT proved an invaluable technique for demonstrating the direct effects of starch retrogradation in a white baguette. Our detailed visualisation of the bread’s internal structure provided clear and detailed insights into how its texture changed over time. Armed with this data, our client could assess the extent of starch retrogradation and validate the impact of using different additives and processing techniques to improve product longevity.

We bring together Micro-CT, microscopy and spectroscopy techniques, to enable you to explore the intricate details, composition and behaviour of materials in your products with unmatched precision and efficiency. Find out more about our service.

1. Gray, J.A. and Bemiller, J.N. (2003), Bread Staling: Molecular Basis and Control. Comprehensive Reviews in Food Science and Food Safety, 2: 1-21

2. Aguirre, J.F., Osella, C.A., Carrara, C.R., Sánchez, H.D. and Buera, M.d.P. (2011), Effect of storage temperature on starch retrogradation of bread staling. Starch/Stärke, 63: 587-593.