They required fast, large-scale support for the qualification and validation of incoming drug component materials. These components – such as pre-filled glass syringes, rubber stoppers and plungers – were arriving in high volumes and needed to be evaluated within a short timeframe to support a critical manufacturing deadline.

The client’s internal teams were facing mounting pressure to process and approve thousands of individual parts across multiple batches. Each component had to meet rigorous metrology, functional, biocompatibility and chemical criteria to ensure compliance.

RSSL worked closely with the client to design a bespoke solution that aligned with their quality assurance standards, technical requirements and accelerated timelines.

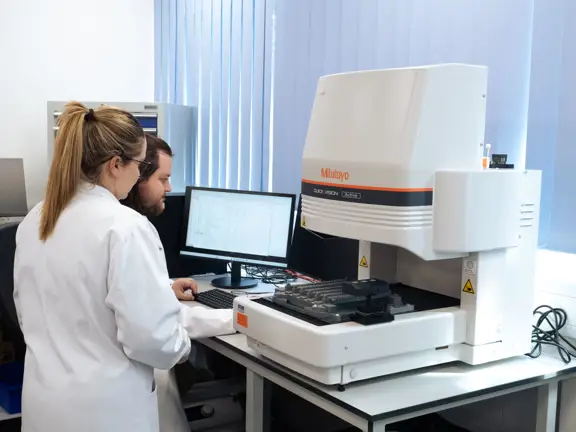

Our multidisciplinary team brought together specialists in metrology and pharmaceutical analysis along with cutting edge calibrated software to create a concise workflow.

Using both manual and automated metrology tools, we performed dimensional analysis to confirm that all components matched the client’s specifications. For glass syringes in particular, we evaluated internal glass stress using polarimetry to identify potential weak points that could lead to future breakages or compromised integrity.

Functional and performance testing was equally critical. We measured glide force to assess how smoothly the plunger could be actuated which is vital for usability and dosage control. Rigid Needle Shield (RNS) removal force was evaluated to ensure that the shield could be removed by the end user without excessive force while still being secure during transport. Needle adhesion testing verified the strength of the bond between the needle and syringe body, protecting the user from malfunction during administration.

Chemical and biocompatibility testing rounded out the qualification process. We carried out pharmacopeial chemical analyses to confirm that all materials complied with relevant standards and posed no risk of interaction with the drug product or the patient.

To meet tight deadlines without compromising data integrity, RSSL implemented a fully automated testing workflow which included CMM, CT Imaging and VMM. To further increase efficiency and repeatability, RSSL used 3D-printed custom sample holders tailored specifically to the dimensions of the client’s components.

These holders ensured consistent positioning during imaging and testing, while maintaining component integrity.

Through a combination of bespoke equipment configuration, automated processes and deep technical expertise, RSSL enabled the rapid, reliable and high-volume assessment of thousands of critical drug components. By combining scientific expertise with innovative problem-solving, RSSL continues to support the development of cutting edge biologics, transforming lives through science, innovation, and collaboration.

Our tailored, high-throughput screening solution delivered the speed, precision and reliability our client needed to uphold the highest quality standards whilst still maintaining tight manufacturing deadlines.