Ensure product sterility and compliance with RSSL’s CCIT services aligned to USP & EP requirements

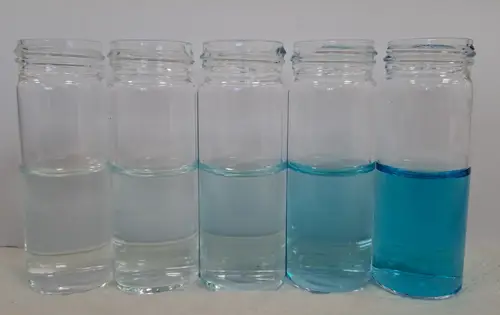

We support the pharmaceutical industry in maintaining the highest standards of sterility and product quality with our Container Closure Integrity Testing (CCIT) services.

Ensuring a container’s closure system remains intact is critical within a stability study for maintaining a sterile barrier throughout a product’s shelf life. A compromised container can allow air, moisture or microorganisms to enter, which can affect drug efficacy, safety and compliance.

A key quality assurance process, Container Closure Integrity Testing evaluates whether packaging systems can maintain sterility under real-world handling and storage conditions. This includes ensuring packaging integrity during transportation and storage, verifying package changes or component compatibility or root cause investigations in quality incidents