Food characterisation isn’t just an effective trouble shooting tool, it can also shape a faster, more efficient product development process. Here, we explore how RSSL’s advanced physical characterisation of food service can help producers solve challenges, explore solutions and accelerate decisions.

By revealing how texture, ingredient interaction and microstructure impact final product quality, food characterisation helps formulators make targeted changes to improve product performance and consistency. Using different techniques to identify potential issues before scale up, such as product instability, poor aeration or unwanted moisture migration, it not only help producers create better products but save them considerable time and resources too.

Take bread, for example. Using an advanced x-ray technique, known as micro-CT, we can create a 3D view of the internal pore structure. Given that the texture largely depends on the distribution and interaction of gluten and starch during processing and baking, these insights allow formulators to see exactly how different flour types, mixing methods and processing parameters affect the final bread structure – giving them a clear path to developing a higher quality product with improved texture, volume and shelf stability.

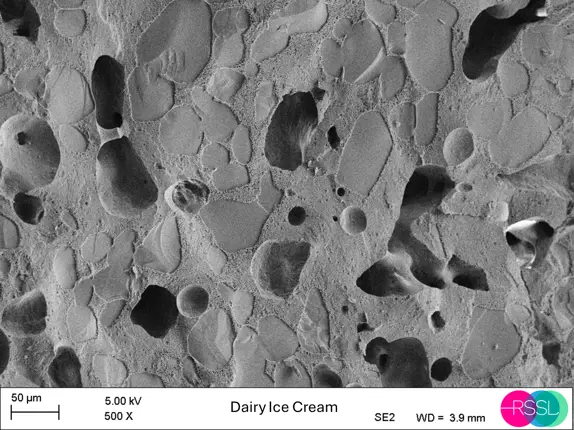

When it comes to ice cream, it’s a question of using a combination of microscopy techniques (both optical and cryo-SEM) to understand the complex system of ice crystals, air bubbles, fat globules and liquid phase.

These components are responsible for the signature creamy mouthfeel consumers expect, so by visualising their size and distribution, formulators gain valuable information that helps them refine recipes and create a truly indulgent eating experience.

This has huge implications for innovation pipelines. We estimate that by preventing reformulation loops and validation delays, early-stage food characterisation can reduce development cycles by between 20-40%.

For instance, RSSL’s food characterisation analysis for a confectionery manufacturer recently helped them create the perfect crispy product coating three months ahead of schedule.

Using two powerful techniques – micro-CT for 3D structural visualisation and Differential Scanning Calorimetry (DSC) for heat flow analysis – we identified air fat interactions affecting coating crispiness and these insights enabled rapid reformulation and successful first-time-right scale up.

In other words, instead of relying solely on sensory or pilot trial feedback, our client used RSSL’s objective data to make faster, more confident decisions.

Of course, we can’t talk about food characterisation without also recognising its equally valuable troubleshooting role. From fat bloom and phase separation to inconsistent baking, coating defects and staling, producers can face any number of unexpected problems after launch or need to adapt product formulations in line with latest regulations, trends or quality demands.

Whatever the issue, this robust data can be used to provide answers - leading to quicker, more effective resolutions.

So why do we recommend investing in food characterisation analysis at the beginning of product development? Because predicting a problem before it happens is always better – and certainly more cost effective – than reacting after the event. Once production-scale issues appear, the scope for change is likely to be limited, particularly when fixed supply chains and incomplete formulation histories are likely to further complicate the situation and make the whole process more time consuming and expensive.

With regulatory and consumer pressure driving demand for more transparency, reformulation and consistency, the need for advanced food characterisation has arguably never been greater. And you don’t have to look far to see why:

For those forward-thinking producers ready to invest in early-characterisation, RSSL provides an advanced food characterisation service. And because it integrates multiple high-resolution analytical platforms and expert interpretation, we can provide a 360◦ view of food microstructure and performance – ensuring the whole product system is fully understood right through to first bite.

Crucially, we link the consumer experience with scientific measurements. By bridging sensory perception, structure and formulation, our robust data becomes commercially meaningful: providing actionable product insights that could make all the difference to product success.

If you want your new product to be a success you need to know how it will perform under different conditions. Our analytical techniques will give you an in-depth understanding of your products physical structure and constituent ingredients, delivering insights that address the development and production challenges that come up along the way.

Contact us now, and whether you are at the beginning of your R&D process, tackling reformulation, or have hit unexpected quality issues, our investigations will give you the answers you need.