BY DANIEL NICOLAU | 18TH APRIL 2023

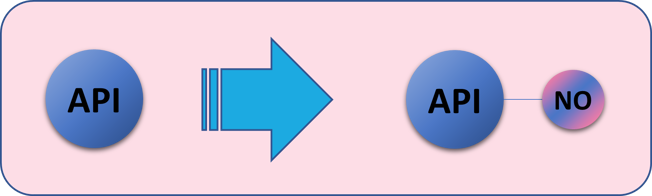

The formation of nitrosamines in pharmaceuticals has been at the forefront of the industry for some years. Their presence in some pharmaceutical products, such as the API ranitidine, sparked a concerted effort by the industry, the US Food and Drug Administration (FDA) and the European Medicines Agency (EMA) regulatory authorities to investigate, risk assess and evaluate all products.

Where it all began

It began with the more commonly known nitrosamines, such as N-Nitroso-dimethylamine (NDMA), which is known to be present in food and natural rubbers. The list of nitrosamines recommended to be analysed by the regulators grew as the chemistry became more understood and relatable to pharmaceutical products. Nitrosamines can potentially be introduced into pharmaceutical products through contamination during processing- for example, by using equipment that has not been adequately cleaned or through exposure to environmental sources of nitrosamines. Factors such as the presence of catalysts or the impact of temperature and pH, allowed risk assessments to be more targeted to the nitrosamines that were more likely to be present- as opposed to some overall screening or attempting to target all nitrosamines.

Why is it in the news now?

Nitrosamine presence has varied from product to product, with changes to the likes of packaging and excipients have settled the nerves of the industry regarding detecting the commonly known nitrosamines, such as NDMA, in their product.