Stage 3 - Claim substantiation and manufacturing

Once the final formula had been established, the next step focused on determining the information that could be included on the product label.

As this vegan product was to be manufactured in a non-dedicated site, any risks of the unintentional presence of animal-derived material needed to be assessed. This was vital given that consumers may use vegan products as a way to avoid animal-derived food allergens, as well as make lifestyle-driven dietary choices.

RSSL carried out a comprehensive assessment of potential risks both within the supply chain and the manufacturing process. The outcome of which would either be used to substantiate a vegan claim or indicate that the unintentional presence of animal-derived allergens needed to be communicated to the consumer.

Supply chain

Our risk assessment began with the supply chain. If the manufacturer was buying in materials that unintentionally contained animal-derived materials, there would be no way to then manage them back out - so this was a fundamental aspect of our overall review.

On-site visits to suppliers were conducted to allow for a full understanding of how the manufacturer managed materials and to assess the evidence that planned controls to minimise the risk of contamination from animal-derived materials were effective. The manufacturer also notified their suppliers that the materials were to be used in a vegan product and needed to meet specific requirements; ensuring open and honest communication.

As the manufacturer did not have the resources or space for a dedicated line, the vegan mayonnaise would be made using shared equipment. RSSL consultants therefore visited the site and reviewed the plans for the manufacturing process, identifying potential areas where there was a risk that could impact the validity of the vegan claim. All stages of the process were considered; from the storage of materials, through to decanting and blending, as well as production and packing.

The potential serious risk of an egg containing product being packed into the vegan packaging in error was also an important part of this stage of the assessment. Labelling of re-work and the process for applying packaging to the line were identified as key areas for improvement, in order to minimise the risk of misuse of ingredients or cross-packing of product.

Cross-contamination risk

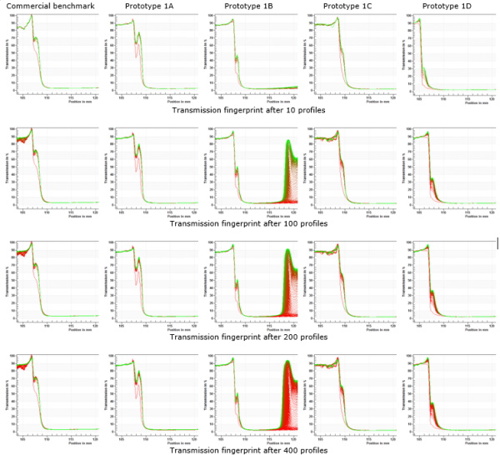

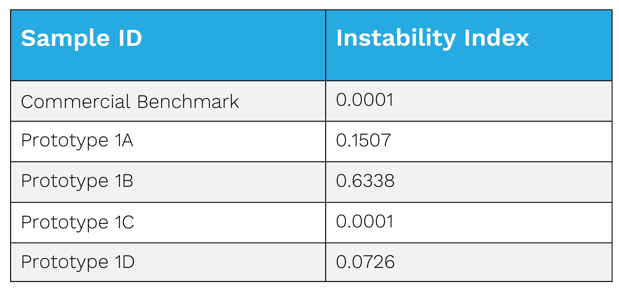

Consideration also had to be given to the risk of cross-contamination through insufficient cleaning of the shared manufacturing equipment. RSSL therefore recommended undertaking a cleaning validation study to assess whether the cleaning procedure was effective at removing the egg mayonnaise from the line and equipment.

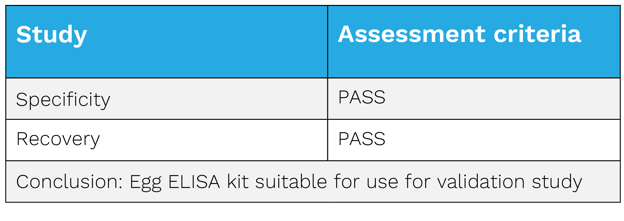

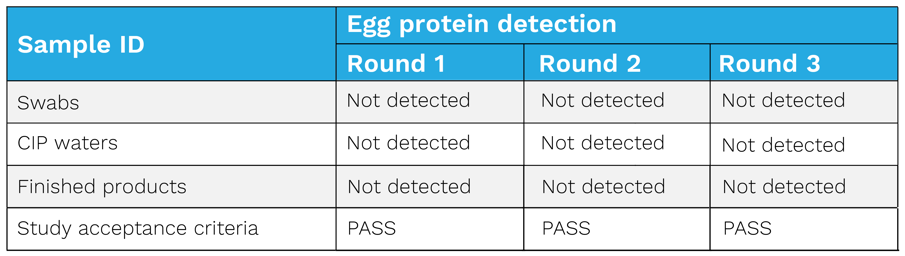

RSSL advised on the sampling points for swabbing; focussing on the hardest to clean areas and different surface types. We further recommended the inclusion of both a positive control sample of the egg mayonnaise and samples of the next-made vegan product. A level of ongoing surveillance testing to substantiate the vegan claim was also advised. Having determined that analytical testing to assess the success of the cleaning procedure was needed, RSSL developed and carried out a bespoke cleaning validation study.