In basic terms, a contaminant is something present in food or drink that shouldn’t be there and generally falls into one of four categories; chemical, physical, microbial and allergenic. It can be present due to agricultural practices, environmental factors, manufacturing, processing, packaging, transport and consumers.

Physical and chemical contamination can be intrinsic to the product itself, such as gristle and bone, or formed by chemical reactions that take place during processing. But it can also enter the food chain from multiple sources.

Factories present many potential risks. Plastic parts and stainless steel metal particles from production lines, as well as cleaning fluids, oils and lubricants are all common suspects. Insects and rodents have also been known to find their way into products via harvested raw materials.

Packaging and storage can also cause contamination issues. External fibres and particles can be the source, as can packaging that breaks down in transit. A plastic tray, for instance, can shatter into multiple tiny shards. Adhesives, containers and wooden pallets are also often found to be the cause of chemical contamination migrating into food and drink products.

Perhaps not surprisingly, consumers can sometimes be the root cause of contamination. Generally, it happens accidentally such as the backwash of medicinal tablets into drinks. However, there are instances where contaminants have been added intentionally to products, either to damage brand reputation or extort money from the manufacturer or retailer.

Although metal detectors installed on production lines will alert manufacturers to some important contaminants, such as ferrous metal, other common foreign bodies can’t be found in this way because the technology is simply not available - plastic is very much a case in point.

Tracing the problem back to the root cause can also be a challenge. A medicinal off taste in a drink, for instance, may be the result of a small leak in the original processing line, which allowed lubricants to enter the product and cause the reactions that then created the unwanted flavour profile.

It’s equally important to be aware that the investigation will be complicated if the contamination originates at the end of the supply chain. Manufacturers don’t have control of products once they leave their site, but the retailer’s storage conditions may be the source of the contamination – making for a time consuming and complex problem solving exercise.

Speed of response is vital. Contamination not only threatens consumer safety and brand reputation, it also raises the very real possibility of an expensive product recall. But companies can only take effective action if they know what it is and where it came from. At RSSL we understand the urgency, which is why we offer an priority response service. It gives customers access to our technical experts 24/7 and provides rapid analytical results, enabling them to make informed, business critical decisions to resolve the situation.

Of course, every contamination project is different and we tailor our approach accordingly. Our state-of-the-art laboratories feature a wide range of analytical technology, from sophisticated microscopes and mass spectrometers to spectrophotometers. We can also use an assortment of quick and simple tests to identify a range of common chemical contaminants such as detergents, bleaching agents and drugs of abuse. Whatever the issue, our analysts apply their extensive expertise to identify and quantify the contamination, while our toxicologists determine if it poses a risk to consumer safety or health. We can also provide equally accurate and reliable root cause analysis, along with legal documentation for court proceedings, if required.

We recommend an integrated approach to risk management. Implementing a Hazard Analysis and Critical Control Points (HACCP) programme in conjunction with a Threat Assessment Critical Control Points (TACCP) plan is a good place to start. HACCP involves identifying potential hazards at each stage of the food production process and implementing controls to prevent or eliminate those hazards. While TACCP can be used to assess the risks of issues such as malicious contamination and tampering.

At the same time, putting several important measures in place will not only help to build a stronger defence, but also ensure the business is prepared to respond swiftly and effectively in the event of a contamination incident:

Of course, every plan should be reviewed regularly and, whenever significant changes have taken place, be subjected to an in-depth review. At the very least, this should involve an annual review of the risk assessment/risk management process to flag any significant developments. The whole planning and execution process must also be well documented.

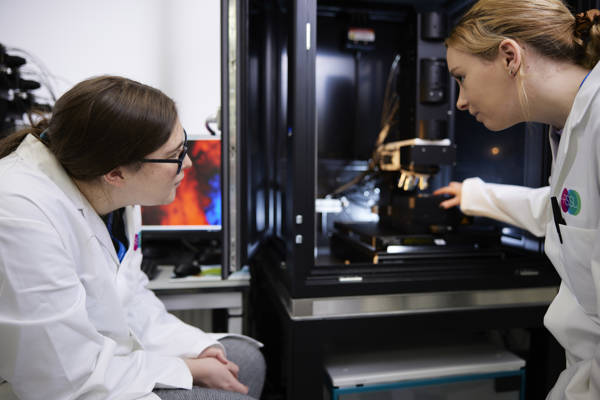

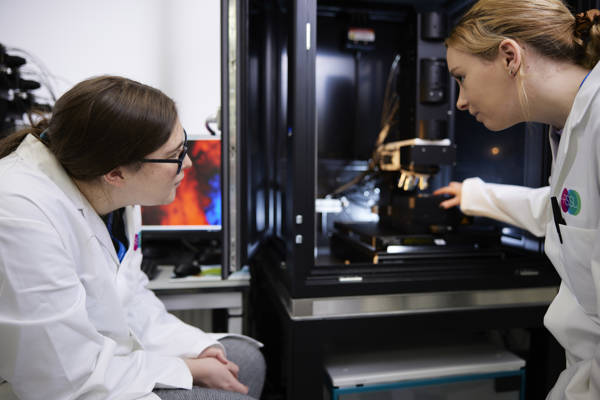

Technical Specialist in our Microscopy laboratory.

Over the last 25 years, she has worked on thousands of foreign body investigations ranging from ordinary pieces of glass and plastic to rodents and sediments causing blockages in filters and pipes.

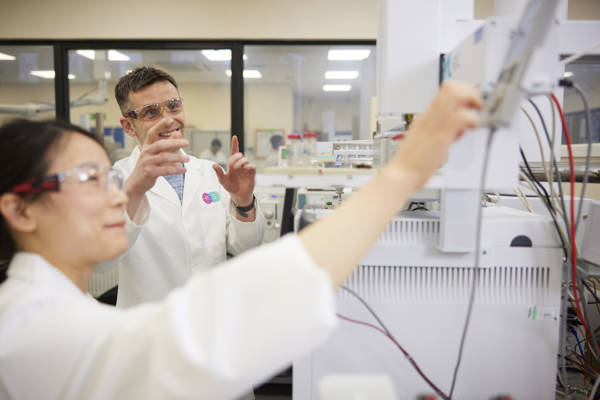

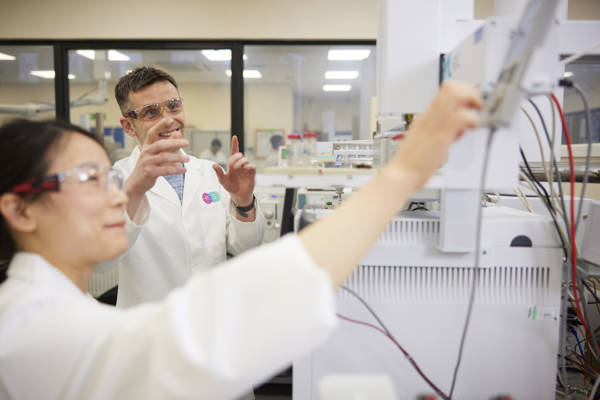

Senior Scientist in our Investigative Analysis Laboratory.

As a technical expert in chromatography and mass spectrometry, Alan uses his extensive knowledge and experience to solve a wide range of chemical contamination issues, ranging from routine taints and flavours to more complex intentionally-added substance investigations.

We have extensive experience and expertise in contamination problem solving and with the latest analytical technologies and our Emergency Response Service we can provide crucial support when you need it most. Our multidisciplinary team of technical experts can identify and quantify physical, chemical and allergen contaminants, our toxicologists can perform risk assessments to determine if there is a risk to public health. We can also support with root cause analysis investigations and implementation of allergen food safety training. If you would like any further information or to make an enquiry, please contact us via the form below.

Switchboard: +44 (0)118 918 4000

Customer Services: +44 (0)118 918 4076